Saving Boeing is the hardest job and biggest opportunity in business

Published in Business News

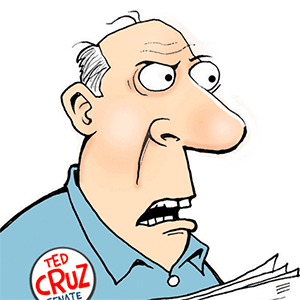

In November, Sen. Ted Cruz, who next month will become chair of the Senate committee overseeing aviation, told new Boeing CEO Kelly Ortberg that if the plane-maker suffered just one more high-profile safety issue, “your company is in deep, deep trouble.”

“I think he’s right,” Ortberg told Boeing employees, relaying the conversation in an all-hands webcast late last month. “We’re at a low here, folks.”

Boeing has endured more than five years of tragedies, mistakes and setbacks: the deadly 737 Max crashes that left the Max fleet grounded for nearly two years; the prolonged stoppage of 787 deliveries due to quality problems; the steep COVID-19 downturn; the midair blowout of a door-sized panel on an Alaska Airlines flight in January; the 53-day Machinist union strike.

With jet production now constrained by regulators and Boeing bleeding more than $4 billion in cash every three months, the scale of the challenge Ortberg faces is daunting.

Recruitment of engineering talent to the ailing aerospace giant is hampered by competition from innovative air taxi and space startups. Layoffs, draining morale, have spurred some top employees to seek jobs elsewhere.

And new obstacles loom next year.

Ortberg must close the $8 billion acquisition of troubled supplier Spirit AeroSystems and smoothly reintegrate that Wichita, Kansas, operation two decades after Boeing sold it off.

And a conversation with President-elect Donald Trump last month told Ortberg to expect a negative impact on Boeing from tariffs in 2025.

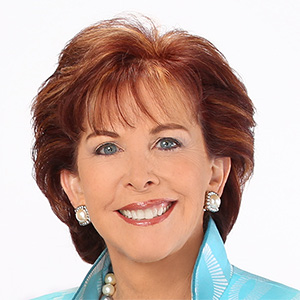

One eminent business leadership guru believes Ortberg has “the hardest job in American business right now.”

Yet Ortberg also has “the biggest opportunity,” said Gautam Mukunda, a lecturer at the Yale School of Management. “Because the man who saves Boeing is going to be a legend of American business.”

There was no big CEO smile or swagger as Ortberg addressed the dire situation during the Nov. 20 internal all-hands presentation, delivered to a small in-person group at the Boeing Field jet delivery center and webcast companywide.

Dressed in a dark Boeing fleece and khakis, Ortberg offered somber realism as he urged everyone in the company to pull together to lift Boeing out of the pit it’s in.

If that can be done, he offered hope that Boeing could come “racing out of this.”

“Our mission is awesome. The product portfolio we have is wonderful. The demand for our products is great,” he told the audience.

“We can turn this around, folks,” Ortberg said. “We can get back to where they’re writing stories about, ‘Wow, look at the Boeing company, and how they’re back to leading aerospace and defense.' ”

But first, he outlined some harsh medicine just ahead: Layoffs, cost cuts, divestments, and a long, slow slog to change Boeing’s culture and restore its tarnished reputation.

Changing the culture

As he’s done repeatedly since he became CEO in August, Ortberg in his presentation, viewed by The Seattle Times, evoked the “Working Together” motto that former Commercial Airplanes CEO Alan Mulally championed in the 1990s during development of Boeing’s successful 777 jet.

That was leadership that explicitly integrated input from all stakeholders: engineers, factory workers, parts suppliers and airline customers.

Employees who spoke with The Seattle Times about Ortberg’s speech welcomed this principle and were generally optimistic that he can lead Boeing out of its current crisis.

However, one engineer and a veteran staffer in the Commercial Airplanes Quality organization, both of whom asked not to be named to protect their positions, expressed disappointment that while Ortberg spoke of culture change he asked that employees move past the strategic errors that have brought Boeing down.

“Don’t sit at the water cooler and bitch,” Ortberg told his audience. “I can’t imagine how much time we’re spending complaining about what McDonnell Douglas did, what Jim McNerney did, what Dennis (Muilenburg) did.”

But overturning what those and other former CEOs wrought since the McDonnell Douglas acquisition 27 years ago — the extreme focus on the share price, the crushing of unions, the squeezing of suppliers, the cost-cutting, the outsourcing of work and treating longtime employees as dispensable — is what many see as the essential culture change.

The quality staffer said he’d have liked Ortberg to first repudiate those past mistakes.

Management professor Mukunda — who described former CEO McNerney, the prime architect of Boeing strategy over the past 20 years, as “arguably the worst CEO in American history” — said going back to Mulally’s pre-McDonnell Douglas “Working Together” culture is exactly what’s needed.

“The intellectual tides of management that used to idolize the GE-style approach that (Harry) Stonecipher and McNerney and (Dave) Calhoun embodied, those tides have turned,” Mukunda said. “That was a disastrous path that the whole country walked down together.”

Still, Ortberg said he wants to get rid of the negativity and firmly focus on the future.

“Everybody is just tired of the drum beat of what’s wrong with Boeing? Right?” he told employees. “I’m tired of it.”

Ortberg said since arriving he’s found too much “internal fighting” and “a blaming culture” at Boeing that tolerates coarse talk and “nasty emails” between employees.

From the outside, this gives Boeing “an aura of a horrible culture,” he added.

“We spend more time arguing within ourselves than we do thinking about Airbus,” Ortberg said.

“There’s a lot of distrust between the people who are doing the work and the people who are managing,” he added. “We’ve got to get much, much more focused on working together.”

A rough start: Cost-cutting and layoffs

Clearly, Ortberg’s recent decision to impose drastic travel and spending cuts and to cut 10% of the workforce is a rough start for a plan hoping to restore employee confidence and morale.

The cost-cutting meant Boeing personnel couldn’t attend an aviation industry conference in Istanbul in September, where a planned debate on stage between Airbus and Boeing executives turned into a solely Airbus presentation.

And at the aviation industry’s Wings Club black-tie awards gala in New York in October, airline customers and aviation consultants took their seats at Boeing-sponsored tables — but without their Boeing hosts. Nonessential executive travel had been nixed.

More significant spending cuts have even been applied to research and development projects.

“You may see some R&D projects that we pause or delay,” Ortberg said. “There are a few that we just decided no longer made sense to do.”

As for the plan to cut about 17,000 jobs through layoffs and attrition, Ortberg told employees that’s necessary because Boeing isn’t producing planes at the rates planned, due to the FAA restrictions imposed after the Jan. 5 blowout on an Alaska flight.

“We continued to staff to a plan that we didn’t achieve, and it no longer reflects our current forecast,” he said. “We’ve got too many employees for the amount of business that we have.”

While some engineers were laid off, most of those cut are not directly working on designing and building planes. One target, Ortberg said, is to cut layers of middle management and give leaders a closer connection to the people working on the factory floor.

“There’s too much management. There’s too much overhead. It’s too hard to get anything done,” Ortberg said. “There’s too many cooks in the kitchen.”

The initial layoff notices went out last month and a second round will be delivered this month, with the designated employees terminated in January and February.

Naturally, this has caused some to begin looking elsewhere.

“People are scared,” said Adam Pilarski, an industry analyst with consulting firm Avitas. He’s received résumés from 20-year veterans at Boeing, including high-level directors.

Stabilizing and streamlining operations

Ortberg had barely begun his tenure as the new CEO of Boeing when he faced two urgent crises: the dire shortage of capital due to the cash outflow each quarter and then the Machinists union strike that stopped jet production for nearly two months.

Pilarski said Ortberg’s immediate concern was “how do we survive?”

Boeing promptly raised more than $21 billion by selling stock and finally ended the strike with a wage hike that compounds to a roughly 43% raise over four years.

In the webcast, Ortberg laid out the next stages of his plan for recovery:

—Stabilize the business with a steady, safe 737 Max production rate ramp-up to generate cash.

—Streamline the company through layoffs and divestment to focus on what’s core and to drive efficiency.

—Take control of ongoing development programs, including the Max 7, Max 10 and 777X jets, as well as a slew of problematic military and space programs.

—Change the company culture to elevate safety and operational excellence.

—Build a future for Boeing by launching in a few years its next new airplane.

Ortberg’s most immediate target is to get the 737 Max production rate up to 38 jets per month, the current cap imposed by the Federal Aviation Administration to ensure manufacturing quality.

Ortberg stressed the urgency of raising jet deliveries to stanch Boeing’s cash outflow, which he projected will be “nearly $4.5 billion” for the final three months of this year. “We don’t have a lot of time to get our act together,” he said.

Still, the manufacturing surge must be done slowly to prevent further serious quality lapses of the sort Cruz warned about. Ortberg said Boeing will use its new safety management system “as our bible” to ratchet up production safely.

Possibly slowing that effort, the complex job of taking over Spirit — which makes fuselages and other major parts for Boeing jets — can begin only when that deal closes around mid-2025.

And the incoming Trump administration may complicate Boeing’s relationship with China, one of the world’s largest commercial airplane markets.

Ortberg told employees he’d spoken with Trump on Nov. 15 to talk about tariffs, emphasizing that “Boeing airplanes are built in the United States of America, exported throughout the world.

“We’re the No. 1 exporter in the country, and there’s no import of Chinese airplanes into the United States,” Ortberg said he told Trump.

The conversation left Ortberg convinced that “we’re going to see some tariffing that, in my opinion, is probably going to be detrimental to us.”

Retaliatory tariffs could delay deliveries to China and blow up Boeing’s plan to clear out the more than 50 completed 737 Maxes built for Chinese airlines and parked since 2019.

“We’re just going to have to work through it,” Ortberg told the employees.

What is core to Boeing?

Ortberg said he’s examining the entire Boeing enterprise to see what units might be sold off to raise cash and restore focus on what is central to Boeing.

“We need to streamline,” Ortberg told the employees, and to divest “the things that really don’t fit in our future.”

“We’re much better off doing less and doing it much, much better,” he said.

Mukunda said Boeing is likely to emerge from Ortberg’s restructuring “a slimmed-down company” focused more sharply on building commercial jets and defense platforms.

Leaks from bankers have revealed Boeing is exploring selling for as much as $6 billion its Englewood, Colorado-based Jeppesen unit, which provides electronic air navigation services.

A sale of the United Launch Alliance, a space rocket joint venture with Lockheed Martin, is reported to be near closing.

Analyst Scott Mikus of Melius Research said another potential candidate for sale could be Boeing’s El Segundo, California-based small satellite unit, Millennium Space Systems.

Boeing’s aircraft parts distribution business and its helicopter manufacturing unit in Philadelphia are also healthy enough to attract buyers if Ortberg chooses.

Boeing is reviewing what to do with the Starliner space capsule program, a failure of which left two astronauts stranded on the International Space Station until next year. It will be tough to find a buyer for Starliner, which seems to have little prospect of making money.

And as SpaceX dominates the launch market, the future of the Space Launch System giant rocket Boeing is developing for NASA is in serious doubt — especially now that SpaceX owner Elon Musk has been assigned the job of cutting government spending for the Trump administration.

A former senior executive at Boeing, speaking on condition of anonymity to maintain relations with current management, lamented that “Boeing used to own human spaceflight and now we’re having a very difficult time even staying in it because of the performance.”

“If they don’t think they can make money in space, they ought to shut it down,” he said.

Boeing has also for years been bleeding money from a series of fixed-price military contracts, which it won by bidding too low. It has no option but to try to complete those contracts and put the massive write-offs behind it.

Byron Callan, a defense analyst with Capital Alpha Partners, says Boeing might want to divest some peripheral military programs, such as the Harpoon and JDAM munitions units.

However, he said the aerospace giant must stay in the market for next generation military aircraft to keep close to advanced developments in core technologies that flow between commercial and defense projects.

“There are parts of the defense portfolio that you could argue should remain part of an aerospace company,” Callan said. “If I were Boeing, I’d want to have a foot that market.”

A new airplane for the future

One certainty is that building commercial airliners will remain Boeing’s center.

“If they don’t think they can make money in space, they ought to shut it down,” he said.

Boeing has also for years been bleeding money from a series of fixed-price military contracts, which it won by bidding too low. It has no option but to try to complete those contracts and put the massive write-offs behind it.

Byron Callan, a defense analyst with Capital Alpha Partners, says Boeing might want to divest some peripheral military programs, such as the Harpoon and JDAM munitions units.

However, he said the aerospace giant must stay in the market for next generation military aircraft to keep close to advanced developments in core technologies that flow between commercial and defense projects.

“There are parts of the defense portfolio that you could argue should remain part of an aerospace company,” Callan said. “If I were Boeing, I’d want to have a foot that market.”

A new airplane for the future

One certainty is that building commercial airliners will remain Boeing’s center.

If successfully launched, Boeing’s next new jet should restore the Pacific Northwest’s waning status as one of the world’s great airplane manufacturing centers.

Before the grounding of the Max in 2019, Boeing’s Puget Sound area factories produced 66 big commercial jets a month. At current rates, those same factories are producing about 30.

Yet Richard Aboulafia, longtime industry expert with AeroDynamic Advisory, worries that Boeing, which saw a brain drain in recent years as veteran employees exited, could soon lose more of the remaining engineering talent it needs to design and build that next plane.

“The more competitive people have every incentive to consider leaving,” he wrote last month. And with many exciting aerospace jobs open elsewhere for top talent, he said, those people won’t be coming back.

“I’m starting to wonder if the odds are now against Boeing coming back, too,” Aboulafia wrote in a November newsletter.

To attract and retain talent, and to attain the “working together” goal, Mikus of Melius Research said Boeing should revamp its compensation structure, perhaps providing stock options even to rank-and-file employees.

Employees need “to feel not only do they have a future in Seattle but that they get to share in the financial benefit of the recovery,” he said.

Ortberg, concluding his internal pep talk to employees, asked for faith in the future and a focus on the immediate steps ahead.

“Let’s get on to next year where the Boeing company is on the ramp back up,” Ortberg said. “It’s going to take all of us.”

©2024 The Seattle Times. Visit seattletimes.com. Distributed by Tribune Content Agency, LLC.

Comments